Contact:

Wei Zhang, 303-492-0652

[email protected]

Philip Taynton, 626-353-2098

[email protected]

Clint Talbott, College of Arts & Sciences, 303-492-6111

[email protected]

Julie Poppen, CU-Boulder media relations, (O) 303-492-4007 or (M) 720-503-4922

[email protected]

Editors: High quality images and cutlines are available at this Dropbox link.

Feb. 15, 2016

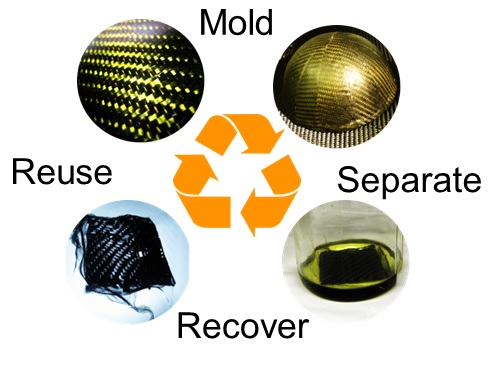

CU-Boulder researchers recycle carbon-fiber composites into new, equally strong material

Carbon-fiber composites – stronger than steel and lighter than aluminum – can easily and cost-effectively be recycled into new material just as robust as the originals, a team of researchers led by the University of Colorado Boulder has found.

Additionally, both the fabrication of the new material and the recycling are energy-efficient and comparatively fast, potentially addressing barriers to wider use in manufacturing. For these reasons, the team’s carbon-fiber composites are “unprecedented,” said Wei Zhang, CU-Boulder associate professor of chemistry and biochemistry.

The findings, published online today in the journal Advanced Materials address a growing issue with these composites, plastic material that gets its brawn from embedded carbon fibers. These composite materials – used in everything from jetliners to fishing poles – are expensive but often used wherever high-strength light-weight ratios and rigidity are required.

Unlike metal, however, carbon-fiber composite is generally not recyclable. The glue that binds the fiber in most carbon-fiber composites can be broken down with expensive, energy-intensive processes that may yield toxic waste. Carbon-fiber composites can also be crushed into a fine powder, but composites made with short fibers are weak.

Millions of pounds of carbon-fiber composites are therefore destined for landfills.

However, “we can achieve complete recyclability” of both the glue and the carbon fiber, Zhang said.

Philip Taynton, who earned his doctorate in Zhang’s laboratory last year, is the lead author of the paper and co-founder of a start-up company working to bring the novel carbon-fiber composite to market.

The company’s name – Mallinda – is itself a composite of the words “malleable” and “industries.” Taynton and Zhang have also discovered a way to make hard but malleable plastics that can be refashioned into new equally strong plastic using just heat or water.

Recycling the team’s carbon-fiber composites simply requires soaking the composite in an organic solution at room temperature.

“That’s it,” Zhang said. “It’s really energy-efficient and eco-friendly.”

Taynton added, “We reuse all of the stuff that we recycle, that we reclaim. There’s nothing we have to throw away.”

Zhang and Taynton noted that the team’s carbon-fiber composite, for which the university’s Technology Transfer Office has filed a U.S. patent application, is more quickly fabricated than most carbon-fiber composites, which can take an hour to cure. The CU-Boulder team’s composites can be formed in 60 seconds.

Mallinda, LLC, which Zhang and Taynton co-founded with CU-Boulder alumnus Chris Kaffer, has gotten $150,000 in support from an NSF Small Business Innovative Research Grant. Kaffer holds a master of business administration from CU-Boulder and a doctoral degree in immunology from the University of California, Berkeley.

The university and Mallinda have signed an exclusive licensing agreement.

"We were very happy with the way that Michael Carr and the TTO worked with us to negotiate terms that are mutually beneficial for both parties," Kaffer said.

The company’s first marketing target is sporting gear such as shin guards. “You can mold it directly to your body, but it will take whatever impact you can throw at it,” Taynton said.

Co-authors on the paper are Chengpu Zhu, Samuel Loob and Yinghua Jin at CU-Boulder; Huagang Ni at Zhejiang Sci-Tech University in Hangzhou, China; and Kai Yu and H. Jerry Qi at the Georgia Institute of Technology.

The research was funded by the National Science Foundation and the Colorado Advanced Industries Accelerator Grant program.

-CU-